| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Model NO. : SP0055

Process : Forming Process

Industry : Metal Stamping Parts

Tolerances : 0.02mm

Customized : Customized

Service : Stamping, Bending, Anodization

Production Process : Laser Cutting Sheet Metal Fabrication

Applications : Auto Part Metal UTV ATV Bracket Furniture

Company Location : Ningbo

Shipment Terms : Fob, CIF,DDU

Shipment Ways : Express /Air Freight /Sea Freight

Delivery Time : 30-45working Days

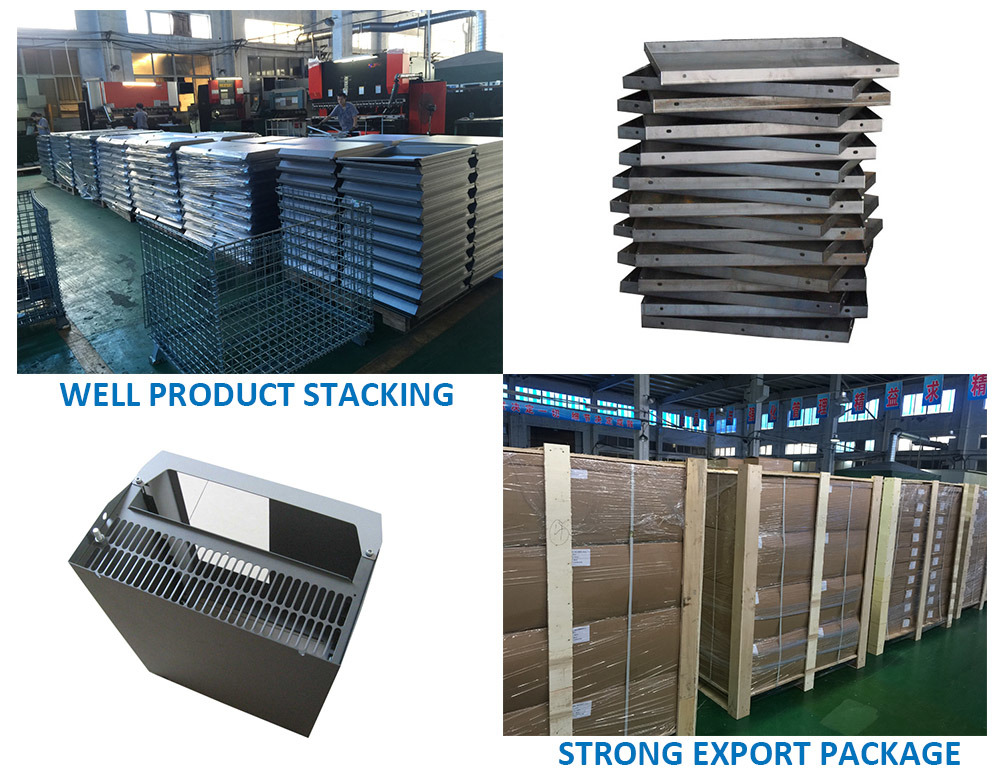

Transport Package : Safety Export Package

Specification : SGS

Trademark : ACE

Origin : Ningbo

HS Code : 7220900000

Supply Ability : Stamping Sheet Metal Product: 50k

Type : Cold Stamping

Processing Type : Shaping Metal

Material : Carbon Steel

Mould : Simple Single Process Dies

Surface Processing : Anodization, Polishing

Fine Blanking : Multi-Position

Customization : Available | Customized Request

MOQ : 1

Specifications

| Specification | As the drawings/samples |

| Color | As your demand |

| Material | SPCC, SECC, SGCC(galvanized steel), Stainless Steel, Carbon Steel, Mild Steel, Aluminum Plate, Aluminium alloy,Copper, Brass etc. |

| Surface Treatment | Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, The wreath oxygen resin spraying, The heat disposing, Hot-dip galvanizing, Black oxide coating, Painting, Powdering, Color zinc-plated, Blue black zinc-plated, Rust preventive oil, Titanium alloy galvanized, Silver plating, Plastic, Electroplating, Anodizing,Passivation etc. |

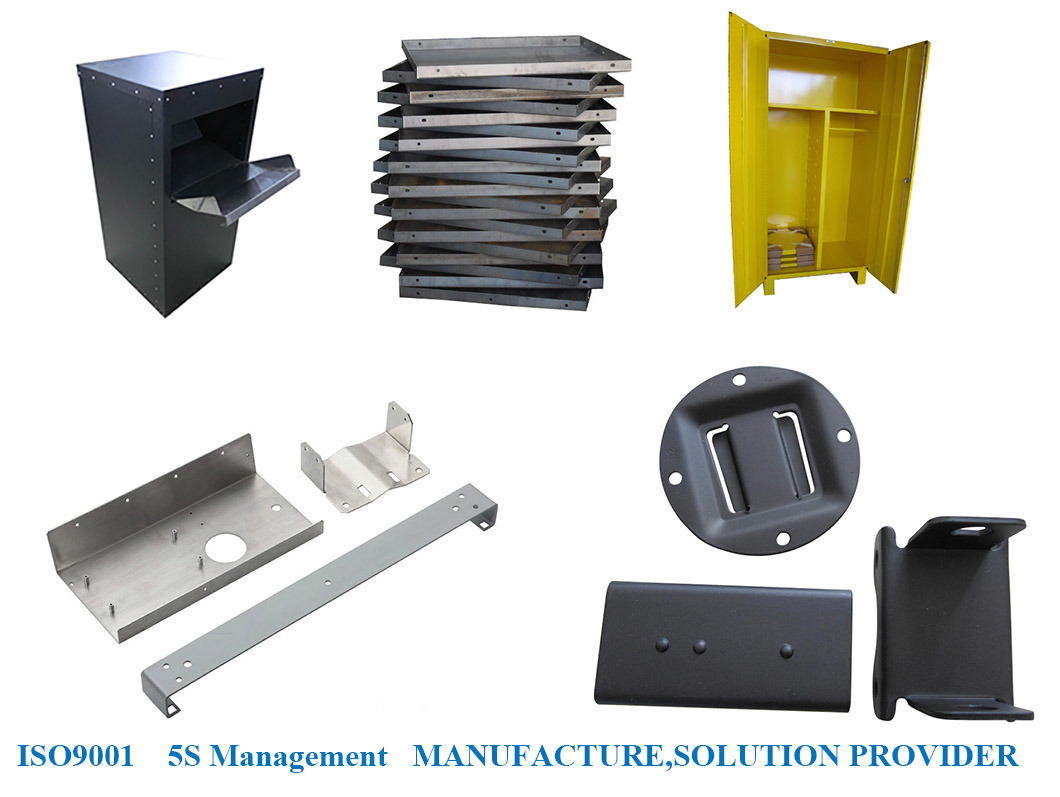

| Applications | Automotive, Instrument, Electrical equipment, Household appliances, Furniture, Mechanical equipment, Daily living equipment, Electronic sports equipment, Light industry products, Sanitation machinery, Market/ Hotel equipment supplies etc. |

| Packaging | As your demand |

| Delivery | 25-35working days, If urgent, need to checking |

About US

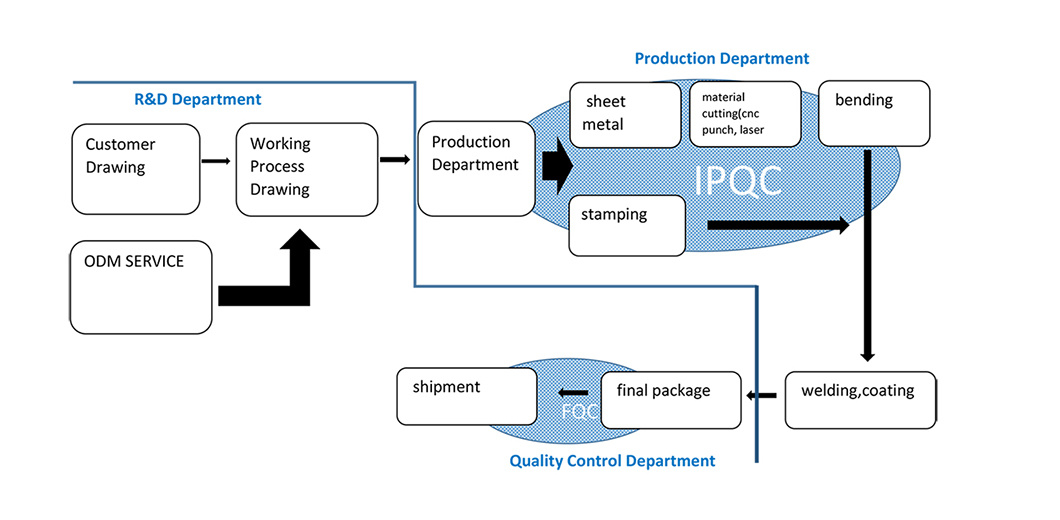

| Our Process | Hi-precision Metal stamping, sheet Metal fabrication, CNC Laser Cutting, CNC Bending, CNC Punch, Laser Welding, Arc Welding, Spot Welding, Stamping, Drilling, etc. (Stamping including: Progressive die stamping, mold stamping,hot stamping, cold stamping ,deep drawn...) |

| Our Max. Stamping Machine Tons. | 200 Tons |

| Our Production Cycles | 30 working days for the new mold and within 10 working days for the exiting model(Depends on the QTY) |

| Our Certificate | ISO9001:2015;ISO14001:2015;IATF16949:2016 |

| Quality Assurance | QC spot check per 2 hours. 100% inspection before shipment. |

| Main Market | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, South Asia, Africa African |

Regular Material

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS316L,SS416 ,AISI 440C,17-4PH etc. |

| Steel/Alloy | mild steel, Carbon steel, 4140, 4340,65Mn,60Si2Mn, Q235, Q345B, 1020steel, 1045steel,A106,A105, A570-50,CR-MO4130,Astm A487 grade 9A, 52100 Bearing steel ,S45c, Sm490A, AVP/S235JRG2,DD14, 1.0037 ,etc, ASTM 1197-47, 25CRMO4V,SCM435, 11SMNPB30,1.0718,.A36 |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H62, H68, H80 ,Bronze 660, C93200,Bronze CDA873 or 956,CDA873,C95600,MAILEABLE IRON ASTM A47-77, etc. |

| Copper | C11000,C12000,C12000 C36000,C100 etc. |

| Aluminum | AL1100,AL6061, Al6063-T6, AL6082, AL7075, AL5052, A380 etc. |

| Iron | 1213, 12L14, 1215,ductile iron astm a536, 60-40-18, 60-45-12, FE E420,etc |

| Plastic | ABS, PC, PE, POM, Delrin 2700 NC010, Nylon, PP,PEI, Peek etc. |

FAQ

Q1. Can I have a sample order?

Yes, we welcome sample order to test and check quality.

Q2. What about the lead time?

1) 5--7 days for normal sample

2) 35--55days for mass production. If urgent,we have green channel.

Q3. Do you have any MOQ limit ?

Low MOQ, 1pc for sample checking is available

Q4. Is it OK to print my logo on product?

Yes. Please inform us your logo or design before mass production

Q5. How to guarantee your quality?

Full sets of inspection equipment.

Raw material inspection before massive production.

QC on line to keep.

100% inspection on package line.

|

|

Ningbo SPCC/Stainless Steel/Aluminum Custom Sheet Metal Stamping Parts Fabrication Service Images |